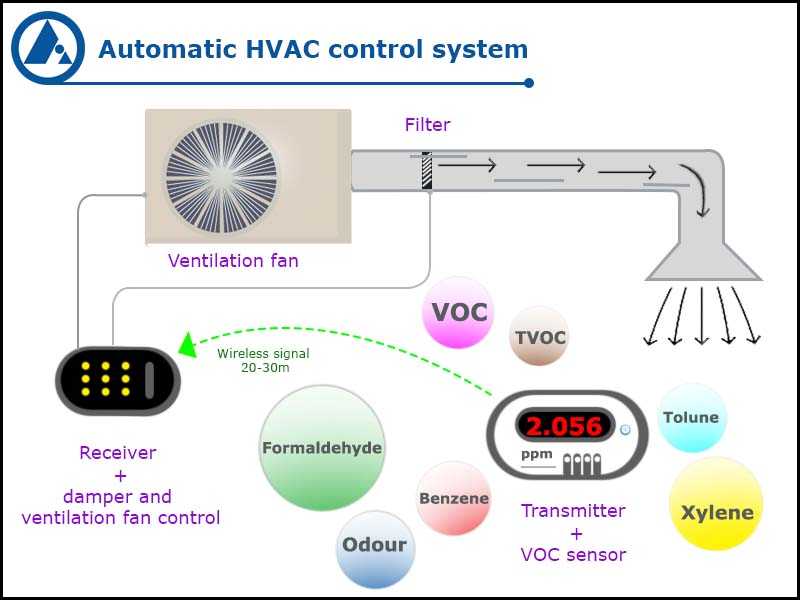

Automatic VOC Control Feedback Mechanism System

VOC monitor + transmitter + receiver + controlling logic for vent dampers

In today’s world, where air quality is becoming an increasing concern, the need for efficient ventilation and air quality control systems is paramount. Volatile Organic Compounds (VOCs) are a significant contributor to indoor air pollution, often emanating from various sources such as paints, cleaning agents, and even humans themselves. VOCs can lead to adverse health effects, including respiratory problems and allergies. Therefore, managing and controlling VOC levels is essential for maintaining a healthy indoor environment.

The Automatic VOC Control Feedback Mechanism System is a cutting-edge solution that tackles this challenge head-on. At its core, this system employs advanced VOC sensors fitted with transmitters strategically placed in indoor spaces. These sensors continuously monitor the concentration of VOCs in the air, providing real-time data on air quality. This data is then transmitted wirelessly to a central receiver unit, which acts as the brain of the system.

The magic happens when the receiver unit processes this information. Based on the VOC levels detected, it autonomously controls ventilation duct dampers and exhaust fans. Here's how it works:

- Monitoring VOC Levels: The VOC sensors work tirelessly, detecting even minor changes in the air's chemical composition. They measure the concentration of VOCs and transmit this data wirelessly.

- Centralized Control: The receiver unit, often placed discreetly within the building's infrastructure, collects data from all sensors. It then analyzes the data to determine if VOC levels are within acceptable limits.

- Dynamic Adjustment: If VOC levels rise beyond the predefined threshold, the system springs into action. It sends signals to the ventilation duct dampers and exhaust fans, adjusting their positions to increase the flow of fresh outdoor air into the indoor space while expelling contaminated air.

- Optimal Air Quality: As a result of these real-time adjustments, the system ensures that indoor air quality remains at an optimal level. It doesn't just rely on a predetermined schedule; it responds dynamically to the actual conditions, providing a constant supply of fresh, clean air.

The Automatic VOC Control Feedback Mechanism System is a game-changer for indoor air quality management. By combining advanced VOC sensing technology with responsive control mechanisms, it helps create healthier and more comfortable living and working environments. With this system in place, you can breathe easy, knowing that the air you and your family or colleagues are inhaling is of the highest quality, free from harmful VOCs and contaminants. It's a step towards a healthier and more sustainable future.

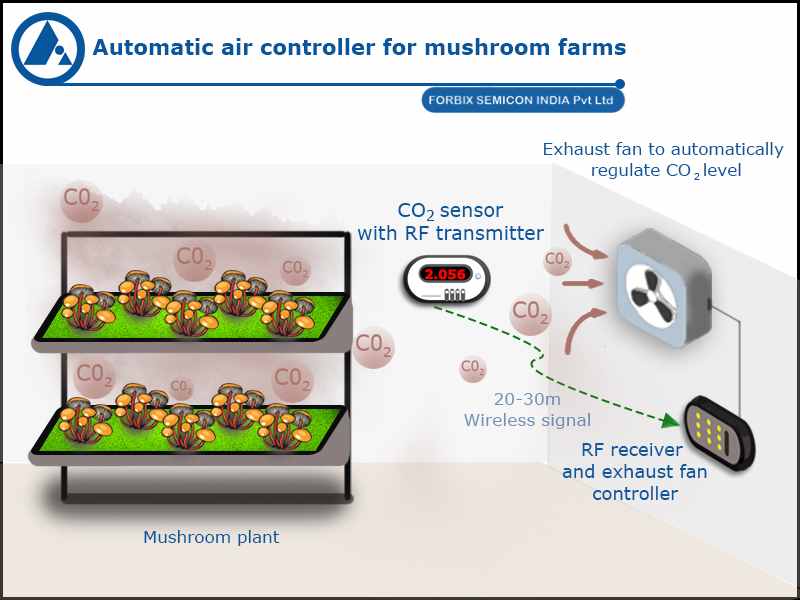

Automatic CO2 Control for Mushroom Farming and Green Building Initiative

CO2 monitor + transmitter + receiver + controlling logic for exhaust fans

In the modern world, where environmental sustainability and efficient resource management are paramount, innovative solutions are continually emerging to address various challenges. One such solution that stands out is the “Automatic Carbon Dioxide (CO2) Control System.” This cutting-edge technology finds applications in both agriculture, particularly in mushroom farming, and green building initiatives. It harnesses the power of indoor CO2 sensors fitted with transmitters and a responsive receiver unit to regulate CO2 levels effectively.

Automatic CO2 control in mushroom farming:

Mushroom farming is a delicate process that relies heavily on maintaining optimal environmental conditions. Carbon dioxide, a natural byproduct of mushroom growth, is crucial for their development. However, excess CO2 can hinder mushroom growth and quality. The Automatic CO2 Control System comes to the rescue by ensuring a consistent CO2 concentration.

How It Works in Mushroom Farming:

- Continuous Monitoring: Indoor CO2 sensors are strategically placed in the growing area. These sensors continuously monitor the CO2 levels and transmit real-time data.

- Precise Regulation: The receiver unit, the system’s core, collects and analyzes CO2 data from the sensors. When CO2 levels begin to rise beyond the desired range, indicating that the mushrooms are producing excess CO2, the system kicks into action.

- Active Ventilation: The receiver unit communicates with exhaust fans and other ventilation mechanisms. It regulates their operation, allowing for increased air exchange to dissipate excess CO2 and maintain the optimal growing conditions.

Green Building Initiative:

Green building initiatives focus on creating sustainable, energy-efficient, and environmentally friendly structures. CO2 control is a critical aspect, as indoor spaces often accumulate higher CO2 levels due to occupancy. The Automatic CO2 Control System aids in maintaining healthy indoor air quality.

- Indoor Air Quality Management: The system’s CO2 sensors monitor indoor air quality. When CO2 levels exceed acceptable limits, indicating poor ventilation or occupancy, the system intervenes.

- Energy-Efficient Ventilation: The receiver unit triggers the ventilation systems to increase airflow, improving indoor air quality. It ensures that only the necessary energy is used for ventilation, contributing to the building’s energy efficiency.

In conclusion, the Automatic CO2 Control System is a versatile and invaluable technology that serves dual purposes in mushroom farming and green building initiatives. By intelligently regulating CO2 levels, it promotes optimal growth in mushroom farms and creates healthier, more sustainable indoor environments. This innovation exemplifies the fusion of technology and environmental stewardship, providing solutions for a greener, more efficient future.